TECHNOLOGY DEVELOPMENT

|

In order to provide affordable and sustainable prosthetic solutions, LIMBS:

In addition to ISO test standards, LIMBS uses four different field tests to evaluate patient outcomes - Physiological Cost Index (PCI), a timed walk test, a GAITRiteTM test and the LIMBS lower limb Functional Parameters Questionnaire (FPQ). The data collected from that program has helped inform design revisions to the knee and make it better suited to meet the needs of patients. Initial test results have shown that compared to other available knees, the LIMBS Relief Knee enables a more normal gait pattern and easier swing through without significant loss of stability. Results from the patient outcomes measurements were presented at the ISPO World Congress in Leipzig, Germany. LIMBS manufactures its knee for distribution to clinics and international organizations. Additionally, LIMBS partners with qualified prosthetic companies to provide components for secondary devices, such as “aqua limbs,” in developed nations. Any/all monies generated from such sales are reinvested into the LIMBS program. |

EVOLUTION OF THE LIMBS KNEE

LIMBS Knees (2004-2019)

THE NEW LIMBS KNEE

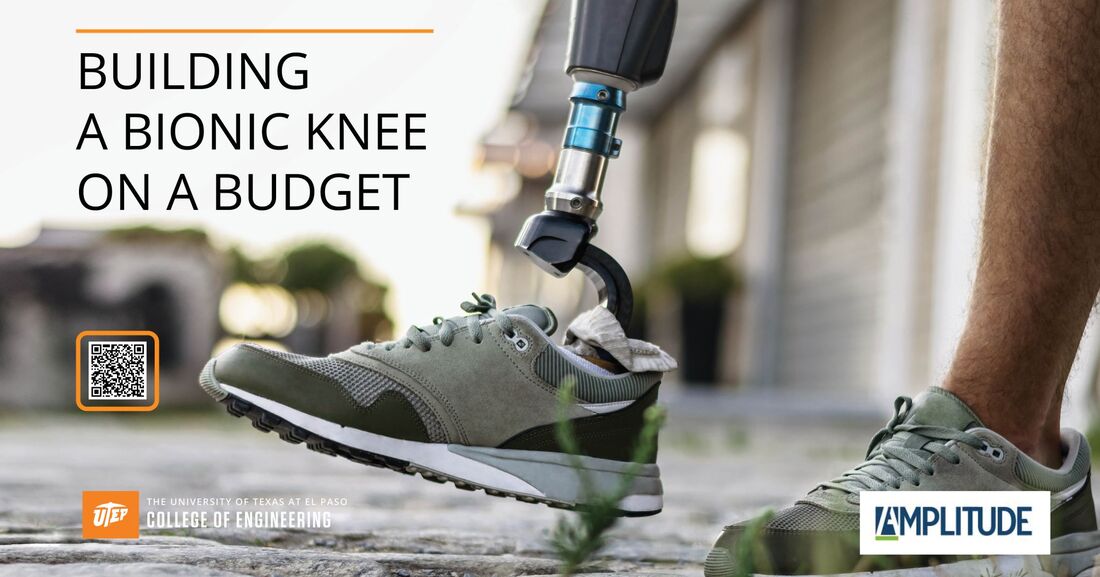

The LIMBS Knee is a great achievement in prosthetics engineering. Since 2004, the LIMBS patented polycentric knee has evolved from a simple joint (that could be manufactured abroad using basic tools) to a highly sophisticated, injection-molded device.

The new LIMBS Knee is stronger, more stable and sleeker than previous generations. There is a greater emphasis on aesthetics, including a protective kneecap that will look more natural under a patient’s clothing and make it easier to kneel.

To evaluate its strength, LIMBS placed the knee under extreme loading conditions and implemented flexion tests. In comparison to other available knees, patients stated it has easier swing-through without significant loss of stability, a more normal gait pattern, lower energy expenditure, and more comfortable sitting and standing.

The new injection molding process can produce thousands of knees every year. Currently, the knees are manufactured and assembled in Mexico using both U.S. and globally-sourced components/materials. Soon, these knees will be distributed around the world to meet the enormous demand for low-cost and reliable prosthetic devices.

(See HISTORY page under the ABOUT tab for more information about the LIMBS Knee.)

The new LIMBS Knee is stronger, more stable and sleeker than previous generations. There is a greater emphasis on aesthetics, including a protective kneecap that will look more natural under a patient’s clothing and make it easier to kneel.

To evaluate its strength, LIMBS placed the knee under extreme loading conditions and implemented flexion tests. In comparison to other available knees, patients stated it has easier swing-through without significant loss of stability, a more normal gait pattern, lower energy expenditure, and more comfortable sitting and standing.

The new injection molding process can produce thousands of knees every year. Currently, the knees are manufactured and assembled in Mexico using both U.S. and globally-sourced components/materials. Soon, these knees will be distributed around the world to meet the enormous demand for low-cost and reliable prosthetic devices.

(See HISTORY page under the ABOUT tab for more information about the LIMBS Knee.)

LATEST RESEARCH

A REMARKABLE DEVELOPMENT IN LOW COST PROSTHETIC TECHNOLOGY

LIMBS new Executive Director and PhD. candidate, Lucas Galey, has published a paper in the peer-reviewed journal, Prosthesis, which describes his low-cost smart-knee, dubbed the "E-Knee." Galey offers proof of concept that "a prototype microprocessor knee can be manufactured for less than $1,000 with comparable stability and user experience to a standard high end device." Galey has been working on the experimental leg system since his undergraduate days. The project is an outgrowth of Galey’s long-term involvement with LIMBS. Click HERE to read the article.

LIMBS new Executive Director and PhD. candidate, Lucas Galey, has published a paper in the peer-reviewed journal, Prosthesis, which describes his low-cost smart-knee, dubbed the "E-Knee." Galey offers proof of concept that "a prototype microprocessor knee can be manufactured for less than $1,000 with comparable stability and user experience to a standard high end device." Galey has been working on the experimental leg system since his undergraduate days. The project is an outgrowth of Galey’s long-term involvement with LIMBS. Click HERE to read the article.

THE NIAGARA/LIMBS FOOT

|

For years, LIMBS International was the largest buyer of the Niagara prosthetic foot. The affordable and high quality foot was explicitly designed for individuals who live and work in rugged conditions in developing nations.

LIMBS has an excellent working partnership with its creator, Rob Gabourie. In 2019, LIMBS purchased the molds and manufacturing rights used to produce the foot. It is now officially called the “Niagara/LIMBS Foot.” Using impact-resistant DuPont Delrin® materials (also used in the LIMBS Knee), the updated Niagara Foot provides superior functionality, stability, durability and energy return capabilities. One of the benefits of the Niagara foot is that one size fits all. A prosthetist can trim the foot to create a smaller foot, and it can fit a patient with a larger foot size by using a foot cover. (Other humanitarian organizations can purchase the foot from LIMBS. Go to the PRODUCTS page under the ABOUT tab for more information.) |