HISTORY

Since 2004, LIMBS International has bridged the gap between technology and affordability. In a world where the majority of research and development is focused on expensive first world solutions, LIMBS is committed to engineering the cost out of prosthetic systems without sacrificing quality. As a result, LIMBS provides amputees with a durable, efficient, stable leg system at a fraction of the cost of other available relief devices.

|

In 2004, the original polycentric knee was developed at LeTourneau University in Longview, Texas when LIMBS International was known as LEGS (LeTourneau Engineering Global Solutions). An engineering professor, and ultimately the founder of LIMBS, Roger Gonzalez, PhD, challenged a group of students to create an inexpensive, highly functional knee that could be fabricated using simple materials and tools, right in the countries where they were desperately needed.

|

When the initial knee joint prototype was ready, the team traveled to a CURE clinic (AIC Bethany Crippled Children's Center) in Kenya to field test their new invention. Based upon the positive outcomes of the original patients and feedback from the clinic's staff, it was the beginning of a great humanitarian endeavor that continues to evolve – making a life-changing impact on the lives of thousands of amputees.

Over the next six years, teams of LEGS/LIMBS engineers, prosthetists and students traveled to many other countries, such as Bangladesh, Sierra Leone, Senegal, India, and Bolivia to train local prosthetists to manufacture the knees, using special custom-made jigs, basic tools and machinery. The model of partnering with existing organizations touches every aspect of LIMBS. This synergy is most evident in the partnerships between LIMBS and international prosthetic clinics that work on the front lines.

Over the next six years, teams of LEGS/LIMBS engineers, prosthetists and students traveled to many other countries, such as Bangladesh, Sierra Leone, Senegal, India, and Bolivia to train local prosthetists to manufacture the knees, using special custom-made jigs, basic tools and machinery. The model of partnering with existing organizations touches every aspect of LIMBS. This synergy is most evident in the partnerships between LIMBS and international prosthetic clinics that work on the front lines.

|

In 2011, in order to maintain better quality control, LIMBS began to work with United Surgery in Bangladesh to produce the LIMBS Knee for greater distribution to clinics and international organizations. Those knees were manufactured and assembled by hand. Now, the revolutionary new LIMBS IM Knee will be injection-molded. (See the TECHNOLOGY DEVELOPMENT page under LIMBS IMPACT tab.)

|

|

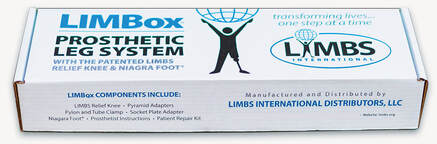

In 2014, LIMBS created the LIMBox® – a ready-to-use, full-leg system. With the exception of a custom-made socket, it contains all the components needed to fit an AK (above-the-knee) amputee, including a LIMBS Knee, pylon, necessary hardware and Niagara Foot. The LIMBox® is distributed to clinics and prosthetists around the world.

|

Students remain an integral part of LIMBS via its partnership with The University of Texas at El Paso. In addition to developing and testing prosthetic devices, they conduct gait analysis sessions using sophisticated motion camera systems to assess patient’s stride length, cadence and energy consumption. (See UTEP STUDENTS page under CONTACT tab).

In 2014, LIMBS launched its Community-Based Rehabilitation (CBR) program. Patients receive pre-prosthetic rehab, gait training, physical therapy and exercises to improve their overall strength, enhance oxygen flow to promote wound healing, decrease scar tissue and minimize pain. Plus, we pay special attention to their emotional and psychological needs. (See COMMUNITY REHAB under LIMBS IMPACT tab).